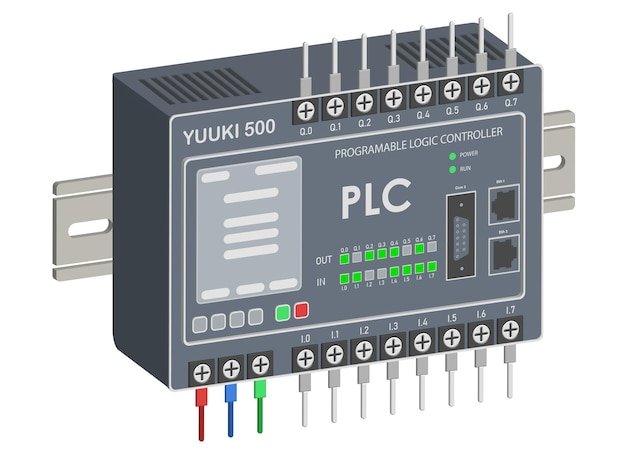

In the evolving landscape of industrial automation Programmable Logic Controllers (PLCs) serve as the backbone of efficient operations. As industries strive for higher efficiency reduced downtime and improved process control PLCs have emerged as an essential component in optimizing industrial utilities. From manufacturing plants to power generation facilities PLCs provide the real-time processing capabilities necessary for seamless and adaptive industrial operations.

The Role of PLCs in Industrial Automation

PLCs are designed to handle complex automation tasks replacing traditional relay-based control systems with a more flexible scalable solution. These microprocessor-based controllers execute logic-based instructions in milliseconds ensuring precision in process automation. Industries leveraging PLCs benefit from enhanced monitoring remote diagnostics and automated control leading to improved asset utilization and operational resilience.

Enhancing Operational Efficiency with PLCs

- Real-Time Process Control – PLCs facilitate high-speed data acquisition and processing allowing industries to monitor critical parameters and adjust operations dynamically. This is particularly beneficial in utilities such as water treatment plants oil and gas refineries and power distribution networks where process fluctuations require rapid intervention.

- Minimizing Downtime – Integrated fault detection and predictive maintenance algorithms within PLC systems help identify issues before they escalate into costly failures. This proactive approach reduces unplanned downtime enhancing overall plant productivity.

- Scalability and Integration – Modern PLCs support industrial communication protocols like Modbus Profibus and Ethernet/IP enabling seamless integration with SCADA DCS and IoT-based monitoring systems. This connectivity allows for centralized control improved data analytics and real-time decision-making.

- Energy Optimization – By enabling precise control of industrial machinery PLCs contribute to energy savings in sectors like HVAC systems conveyor networks and material handling. Optimized load distribution and automated energy management improve sustainability and reduce operational costs.

Future Trends in PLC Technology

The integration of Artificial Intelligence (AI) and Industrial IoT (IIoT) with PLCs is transforming industrial automation. Edge computing capabilities within PLCs enable localized data processing reducing latency and enhancing system responsiveness. Furthermore the advent of cloud-based PLC programming facilitates remote diagnostics firmware updates and predictive analytics making industrial utilities more adaptive to dynamic operational demands.

PLCs play a pivotal role in optimizing industrial utilities by ensuring reliability scalability and efficiency. As industries advance toward smart automation the adoption of next-generation PLCs integrated with AI and IIoT will redefine industrial process control. Companies investing in PLC-driven automation will gain a competitive edge by enhancing system resilience minimizing operational risks and improving productivity in an increasingly digital industrial landscape.